Design & Fabrication

Design for galvanizing

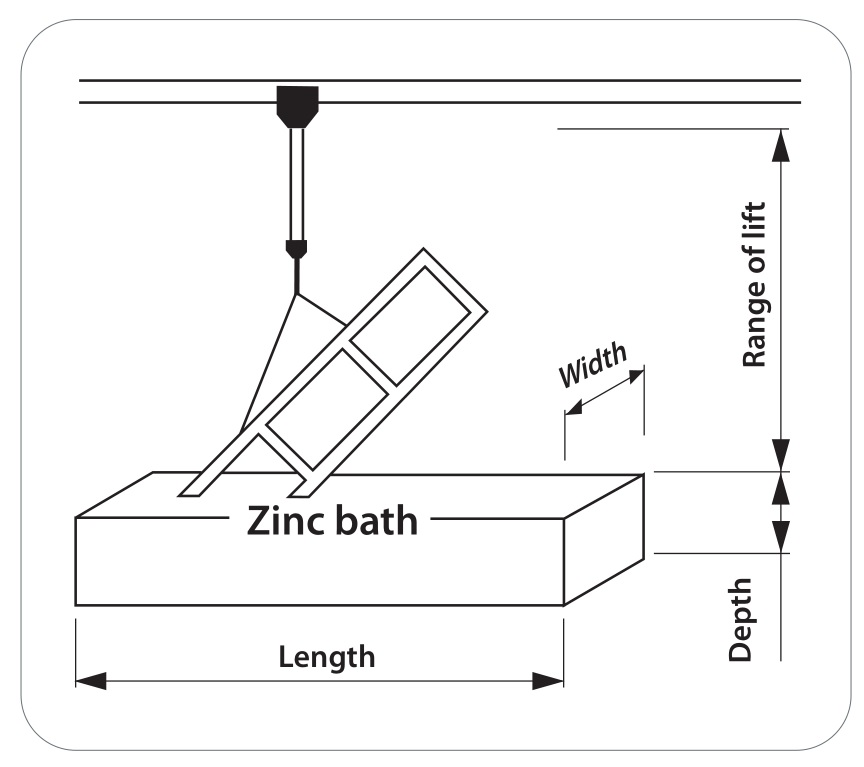

Want the best possible finish on your galvanized steelwork? Well designed steelwork lends itself to a smooth clean finish when galvanized. The first question you should ask yourself is: How suitable is this article for dipping in a bath of molten zinc?

The primary reason for vent and drain holes is to allow air to be evacuated, permitting the object to be completely immersed into cleaning solutions and molten zinc. Proper sizing and location of the holes make it safer to galvanize and provide an optimal finish. The secondary reason for venting/drainage is to prevent damage to the parts.

Basic rules of Venting & Draining

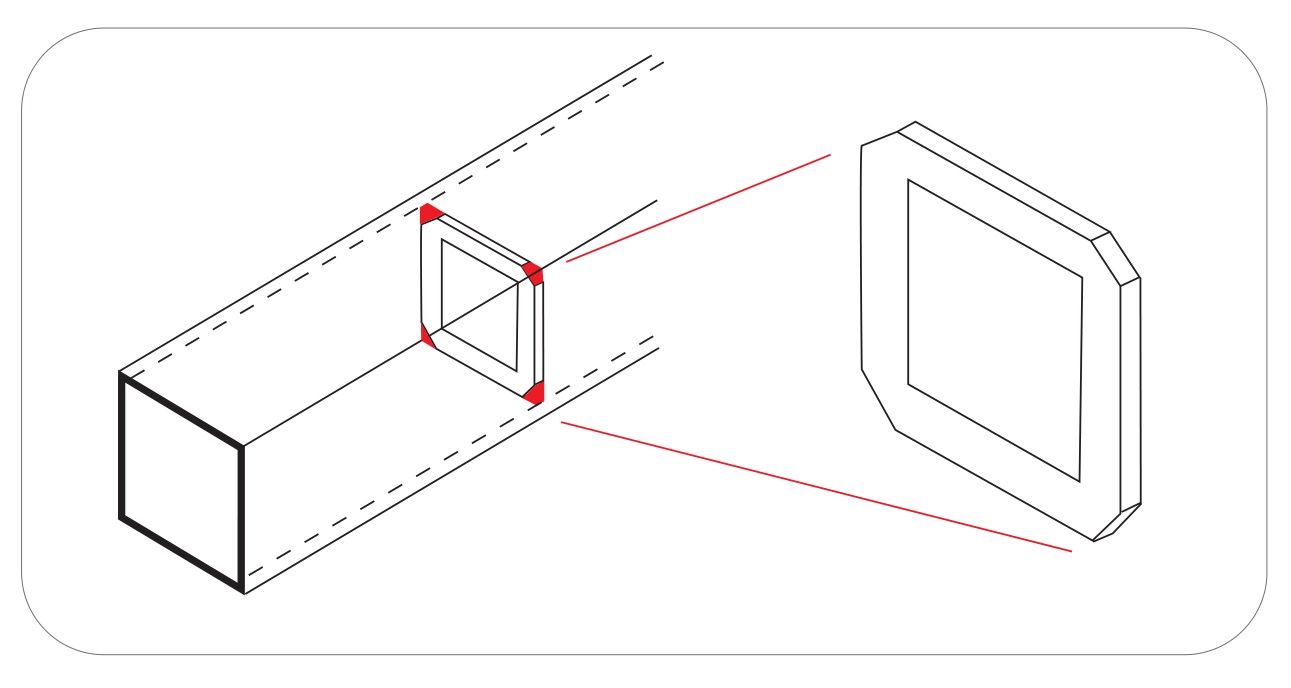

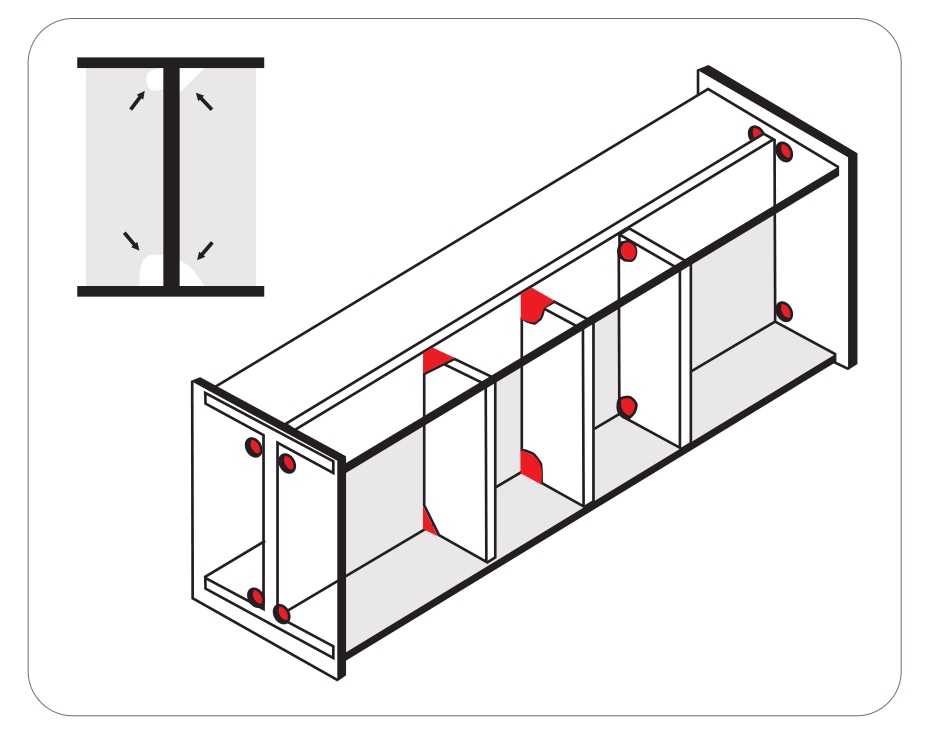

You must allow for the free flow of molten zinc throughout your fabrication. Every enclosed section or overlapping plate must have adequate holes.

- No hole should be less than 10mm

- Preferred minimum hole is 12mm

- For hollow sections the absolute minimum hole diameters are as follows:

| Diameter width of hollow section (mm) | Minimum size of hole (mm) |

|---|---|

| <25 | 10 |

| >25 to 50 | 12 |

| >50 to 100 | 16 |

| >100 to 150 | 20 |

| >150 | Consult Galco |

- Holes should be located at the ends of hollow sections arranged in diagonally opposite pairs

- The method of suspension of the fabrication (see below) should be borne in mind when preparing holes.

- The preferred method is to crop, punch or drill holes

- Concealed / internal venting is not acceptable

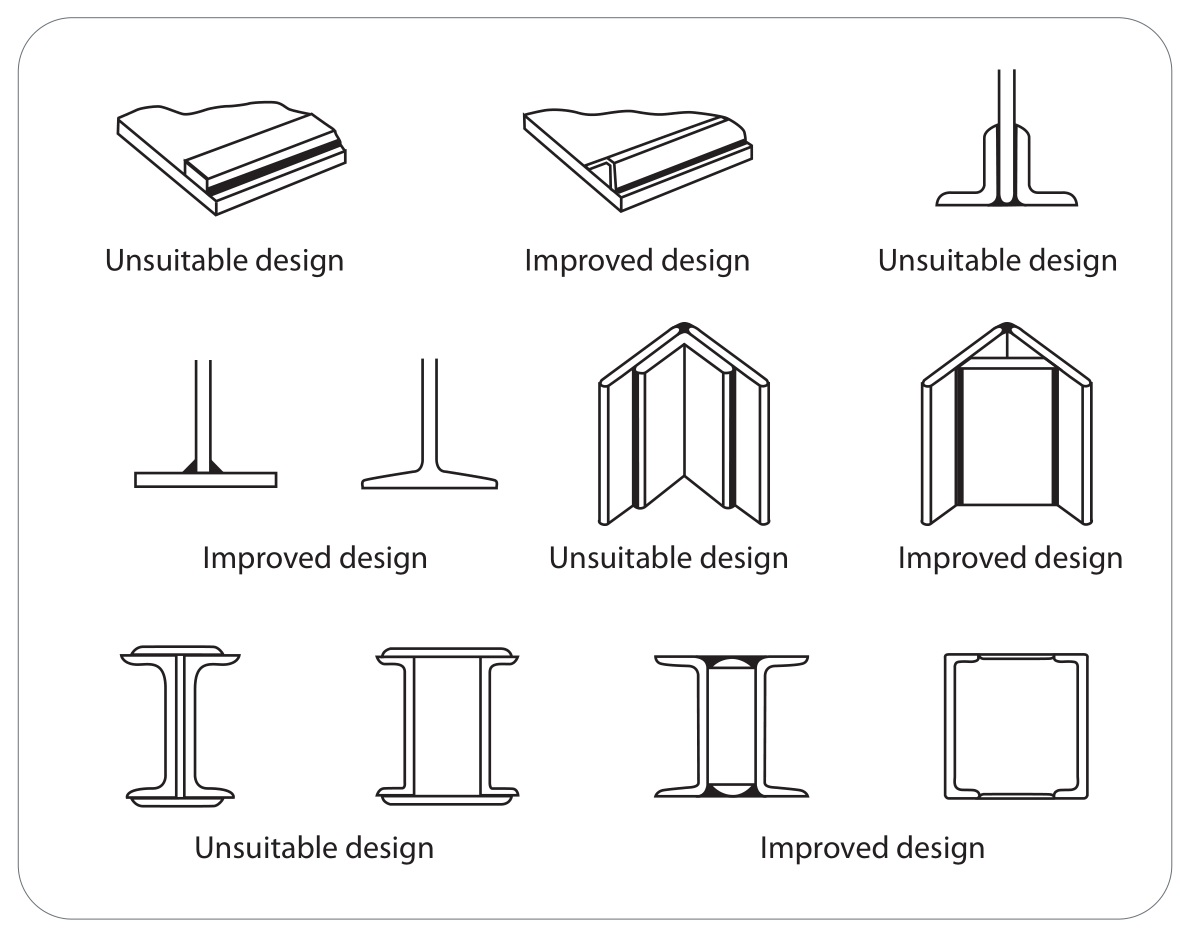

Sections incorporating internal diaphragms and end flanges must also be properly vented. With small rectangular hollow sections, the four corners of the diaphragm plates should be cropped. Larger hollow sections should incorporate an additional ‘manhole’ at the centre of the diaphgram.

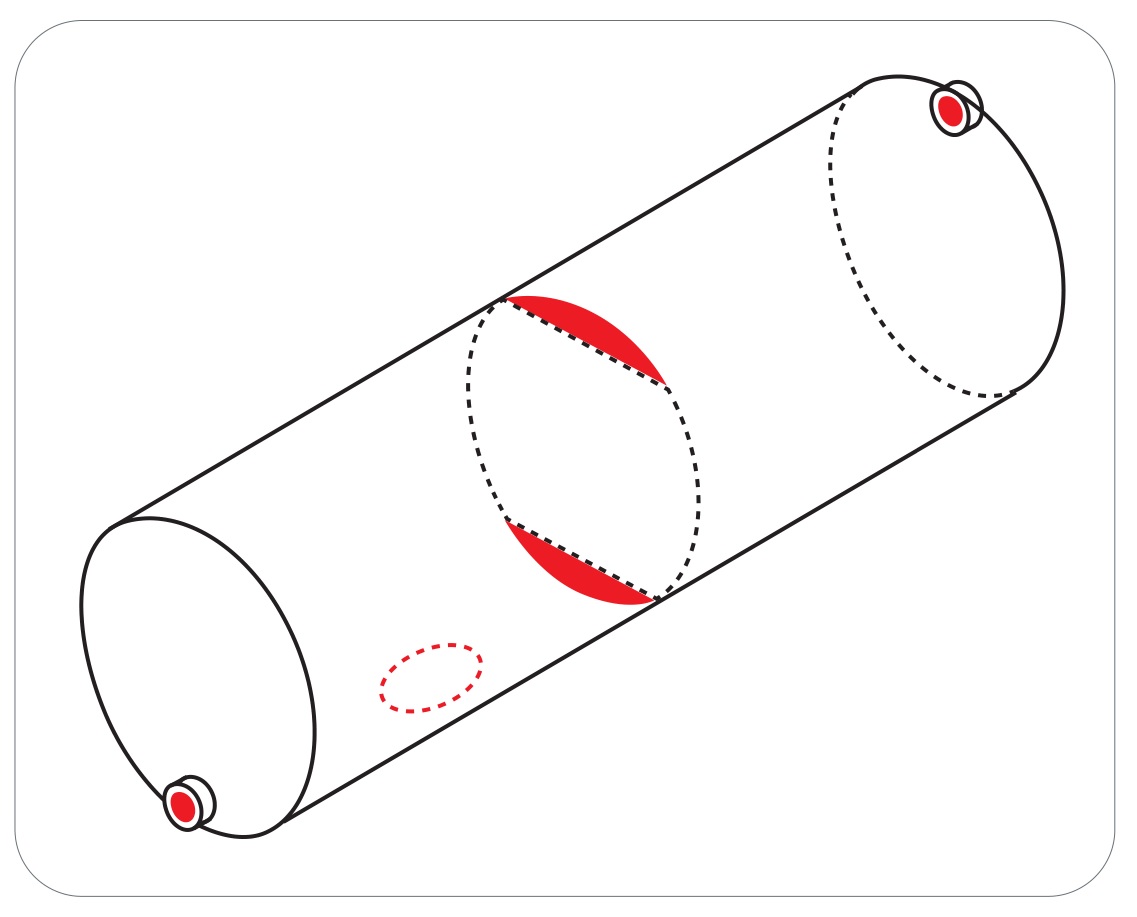

- When an item is immersed in process solutions or molten zinc, the liquids have to flow freely in and out. The viscosity of molten zinc and its density are important factors in designing

adequate drainage into fabrications. - To ensure total protection it is important that the liquids can reach into every corner and crevice – especially with hollow components.

- Any air trapped in pockets will prevent the preparation chemicals adequately preparing the surface and prevent the zinc from reacting with the steel.

- If drain holes are too small, the zinc will not be able to enter quickly enough and the item may be become buoyant causing it to float off the jig or be subject to erratic immersion

Safety Considerations

Hot Dip Galvanizing involves the immersion of materials in baths of acid and molten zinc. This means that all hollow section such as pipes and tubing as well as overlapping plates must be provided with holes for drainage and venting purposes.

If a sufficient number of holes are not provided, air process fluids can get trapped. When dipped in the zinc bath at 450 o C the vapour pressure can rise to 200 bar and blow open the fabrication.

There is a serious risk of injury to personnel and damage to materials when these explosions occur.

It should be possible to view the interior of the vessel through either the vent holes or an inspection hole. Holes/Lugs must be provided so the fabrication may be hung by wires onto jigs.

External Stiffners on open sections should incorporate cropped corners or drainage holes to eliminate dead pockets.

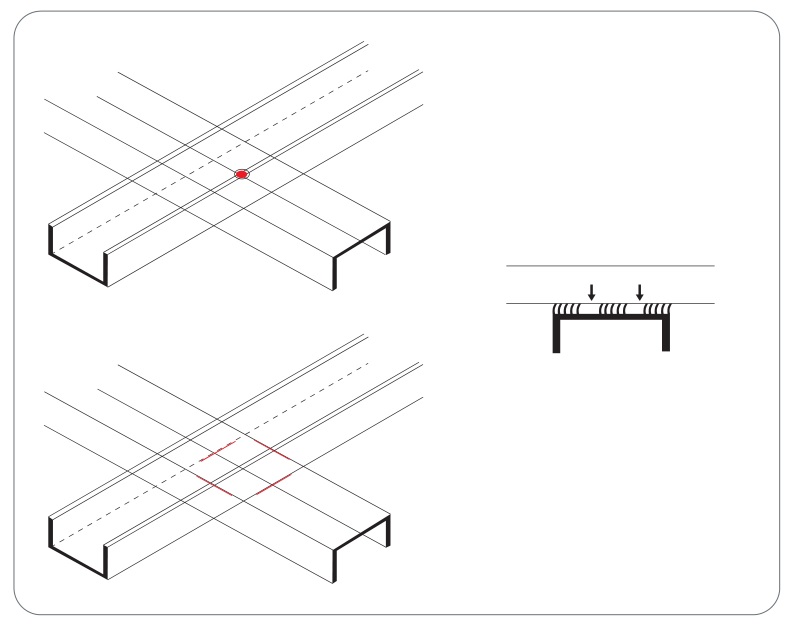

Overlapping / Double plates

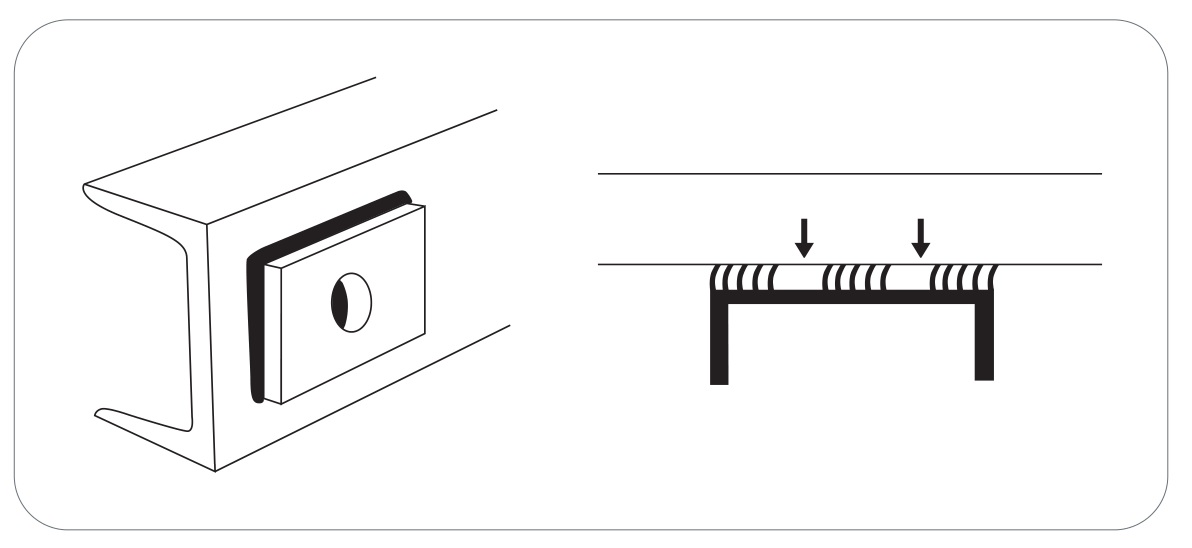

If contacting surfaces cannot be avoided, as with the channels below, then the edges of the contacting area should be continuously welded and a hole drilled trough both members to eliminate the danger of an explosion in the galvanizing bath.

If this is not possible stitch welding should be used. There may be some weeping stains from acid residues trapped between the plates but this will not be detrimental to the protection given by the coating.

It will not generally be necessary to make any provision if the enclosed area is less than 70 mm x 70 mm.

Where designs cannot avoid large areas with double plates (e.g. flange to flange and plate along flange) advice must be sought from Galco as to the correct method of venting.

Castings

Poor quality castings may absorb process fluids that will hinder the galvanizing process. Always check with your supplier that you are getting mild steel castings that are suitable for hot dip galvanizing.

Dissimilar Steels

As hot dip galvanizing is an alloying process it draws out the varying components of the individual piece of steel. This can result in significant colour variations between round bar and box section or between channel and tubing.

Distortion

There can also be an issue if you combine light and heavy sections. These will be dipped at 450 C and will cool down at different rates. This may cause them to pull against one another.

Welding

Pinholes in welds may also absorb process fluids and hinder the galvanizing process. These may leak out after galvanizing and form a brown stain on your steel. This is easily removed and will not recur.

If you would like advice on any aspect of design, please phone us or send us a drawing of the item you would like to dip. This often allows us to recommend some simple alterations that will provide you with the optimum finish.

Contact our team

Over the past 50 years, Galco has become a recognized leader offering high quality equipment and systems. We are dedicated to exploring the latest construction technologies to generate cost savings for clients.

Send Us a Message

Fields marked with an * are required

"*" indicates required fields