RECYFIX MONOTEC

RECYFIX MONOTEC is a new high capacity channel system for the surface drainage of pavements, bicycle routes, car/van parks and roadways in and around residential, commercial and light industrial areas where the channels need to have high lateral strength, are capable of withstanding continuous compressive loads and where ease of installation is a major consideration.

Specifying RECYFIX MONOTEC allows hydraulic engineers and contractor’s wide flexibility during the design and installation stages by reducing the number of channel runs normally required to drain a large area. The reduction means less materials being used and fewer underground excavations, all resulting in an easy and fast installation procedure.

RECYFIX MONOTEC channels are certified in accordance with EN 1433. The CE symbol, external monitoring and the conformity declaration are the guarantee of a maximum technical and qualitative standard.

RECYFIX MONOTEC Load Test

100% Corrosion Free

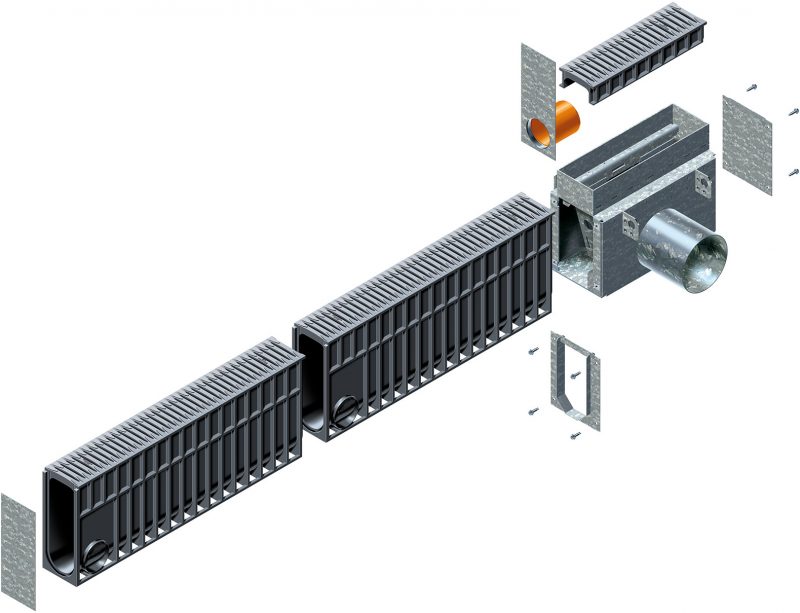

RECYFIX MONOTEC channels made of modified polypropylene, according to DIN EN 1433, CE-conform. Trash box made of galvanized steel with pipe connection possibility DN 200. Removable grating made of modified polypropylene for access to channel system. Connection plate for flexible connection of different channel types with the trash box and closing cap for the closing of trash box. End caps for channel start/channel end (DN 100). RECYFIX MONOTEC channels meet the requirements of DIN EN 1433 and are suitable for the following load classes: C250, D400.

FIBRETEC slotted grating

FIBRETEC slotted grating is specially designed for maximum hydraulic performance. Optimized inlet radii ensure that the largest amount of water is led into the channel within the shortest time. More than one million channels sold expresses its great popularity. Deliberately, the design has now been transferred to the RECYFIX MONOTEC. Along with the enormous volume of the channel, a product with the highest hydraulic demands has emerged – the perfect combination of water intake, retention and drainage.

Optimal hydraulic capacity through slim design

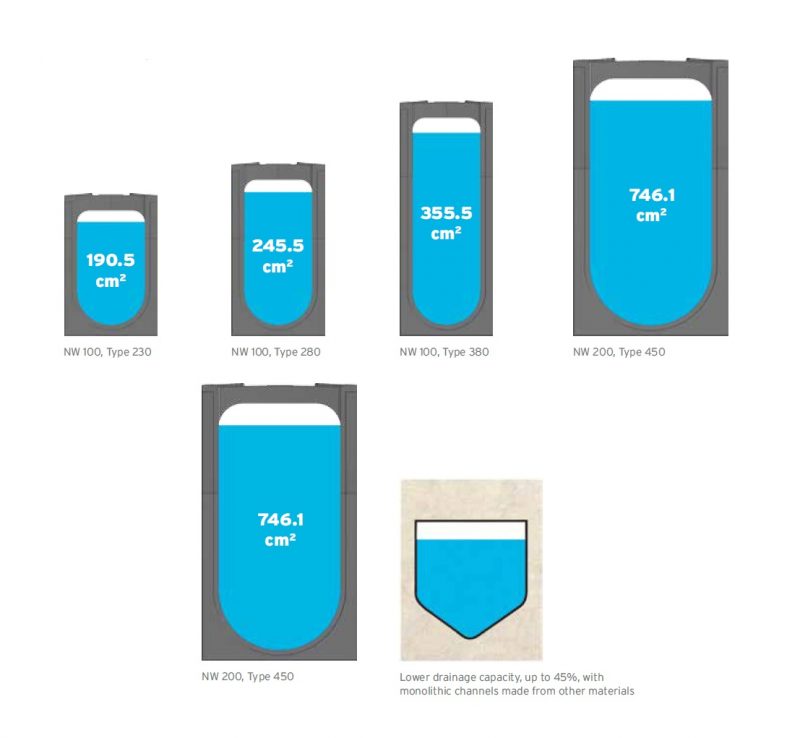

The RECYFIX MONOTEC channel is made of highly resistant and unbreakable polypropylene. Therefore, a particularly slender design is possible which has a positive effect with regard to drainage capacity.

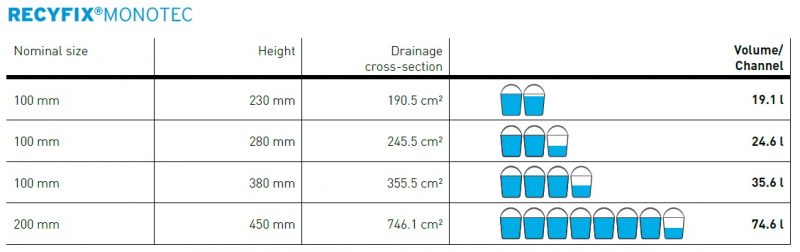

The smallest model, with a nominal width of 100 mm and a height of 230 mm, already achieves a drainage cross-section of 190.5 cm2. Monolithic channels, made from other materials, must have much thicker sidewalls which significantly reduces the drainage cross-section.

The RECYFIX MONOTEC Channel range consists of 3 heights with a nominal width of 100 mm and one model with a nominal width of 200 mm.

Long-term practical tests and computer-aided simulations lead to the same result: The RECYFIX MONOTEC accumulates heavy rainfall, provides a sufficient backwater reserve and drains large surfaces safety and reliably.

The benefits of the RECYFIX MONOTEC

RECYFIX MONOTEC – Installation instructions

Our installation instructions / examples are suggestions that are generally accepted in the trade. Any special installation details required due to local conditions need to be specified by a qualified engineer. Technical regulatory instruments and guidelines applicable in the respective state or country should be taken into account for installation.

- The channel must be supported on the right and left with C20/25 X0 or, if there is a risk of frost, with C25/30 XF1 concrete backing.

- It is important to ensure that the adjoining surface finish permanently covers the channel’s upper edge by 3 to 5 mm.

- If horizontal forces are likely to occur when the channels are installed – such as in concrete areas and reinforced concrete constructions – effective expansion joints must be provided in cross and longitudinal directions in accordance with DIN 18318.

- The lateral stability of the RECYFIX MONOTEC channel body ensures that no damage resulting from dynamic loads occurs when the channels are concreted-in in accordance with instructions. It is not necessary to apply additional reinforcements.

- When installing the channels in surfaces with paviours/slabs, the joints along the runs must be filled with bitumen-based joint filler. Where extreme thrust forces may occur, e.g. along sloping surfaces, special additional measures are required (supplied by others). For detailed information, please enquire.

- This installation advice applies analogously to the inlet boxes.

Paved surface

Concrete surface

our team

Over the past 50 years, Galco has become a recognized leader offering high quality equipment and systems. We are dedicated to exploring the latest construction technologies to generate cost savings for clients.

Send Us a Message

Fields marked with an * are required

"*" indicates required fields