Hot Dip Galvanizing is widely regarded as one of the most effective methods of corrosion protection for steel and the most popular protective process for all external steelwork. The principle reason for this is a combination of cost effectiveness and the extended life expectancy provided by effective corrosion control.

Hot Dip Galvanizing is unique, tough, long lasting, self-healing and covers internal and external surfaces.

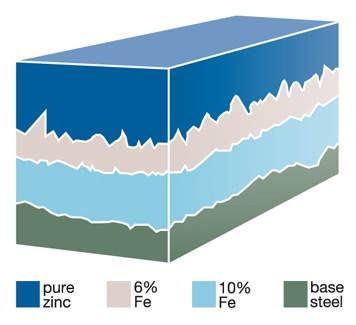

Hot Dip Galvanizing provides a barrier between all internal and external steel surfaces and their environment. The steel is given maximum protection through the formation of continuous, tough, alloy layers that result in a metallurgically bonded coating.

Protection by sacrificial action

Zinc corrodes in preference to steel and sacrifices itself to protect the steel. If the steel is damaged the corrosion products from the zinc are deposited on the damaged area resealing it from the atmosphere and therefore preventing the sideways creep of corrosion. Hot Dip Galvanizing differs from paints in this respect as most paints give no protection at points of damage and only provide barrier protection.

Atmospheric corrosion resistance

Barrier protection

The resistance of zinc to atmospheric corrosion depends on a protective film, which forms on the surface of the zinc. This zinc coating reacts with the atmosphere to form zinc compounds that form a protective, chemically inert, layer that inhibits further reaction with the metal beneath.

The corrosion rate for zinc is generally linear for a given environment. A major advantage of this is that it allows predictions of ultimate life to be made on the basis of interim assessments of coating thickness.

The unique nature of the galvanizing process provides a tough and abrasion resistant coating which means less site damage and speedy erection of structures.

It is estimated that corrosion costs economies around 4% of Gross Domestic Product.

Every 90 seconds, across the world, one tonne of steel turns to rust. Of every two tonnes of steel produced, one tonne is made to replace one that has rusted. The use of hot dip galvanizing to prevent rust means that for every one tonne of steel protected we conserve enough energy to satisfy an average family’s energy needs for several weeks.