Services

About Galvanizing

There’s no other corrosion protection system that provides the long life, durability and reliable performance of galvanizing. To ensure optimum results — reduced coating costs, quick turnaround times and safety of personnel — there are a number factors that must be taken into consideration prior to fabrication. These include:

The Galco group offers a friendly efficient service with guaranteed turnarounds. 80% of steelwork coming into us is galvanized within 5 working days. If you need something galvanized urgently please make sure to let one of our customer service personnel know and they will do everything possible to look after you.

We offer a transport service in many areas on a weekly or twice weekly basis. If you need your steel picked up please enquire if we have a truck in your area.

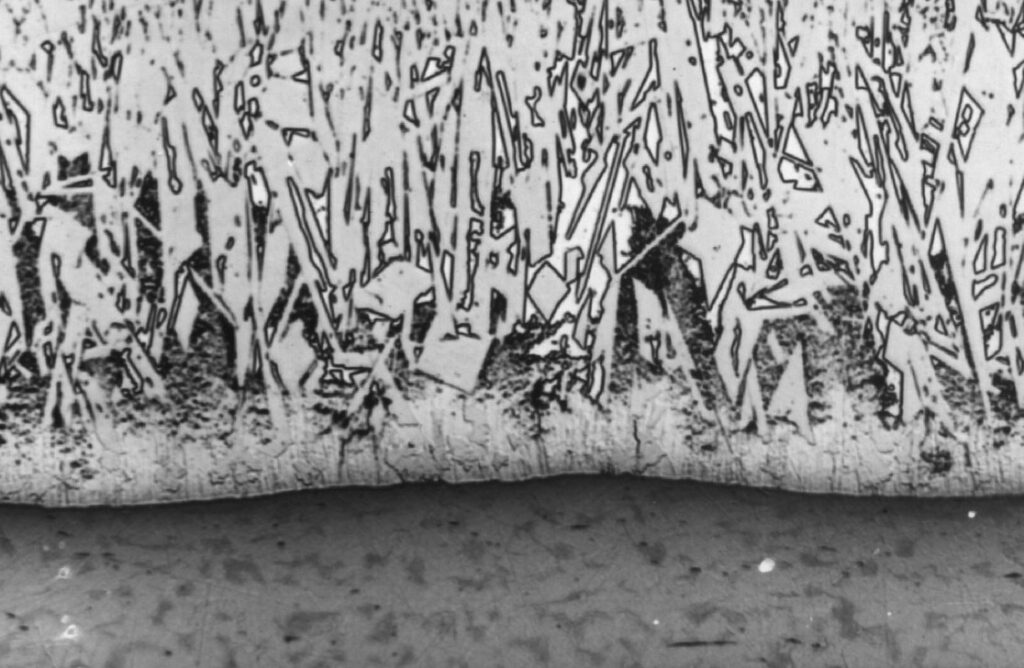

The formation of the zinc-iron alloy coating depends principally on the chemical composition of the steel. All common steels and cast irons can be hot dip galvanized, but steels with particular silicon contents may produce a very fast reaction between the iron and the zinc. LEARN MORE

A metallurgically clean steel surface is an absolute necessity for satisfactory hot dip galvanizing. However, steel surfaces are normally covered with contamination or corrosion products as a result of their chemical composition, manufacture, subsequent treatment or their previous use. LEARN MORE

Fabrication dimensions, weights and other related factors are very important in the hot dip galvanizing process and a communication chain is encouraged between the specifier, fabricator and the galvanizer to limit any problems which might arise during the process. LEARN MORE

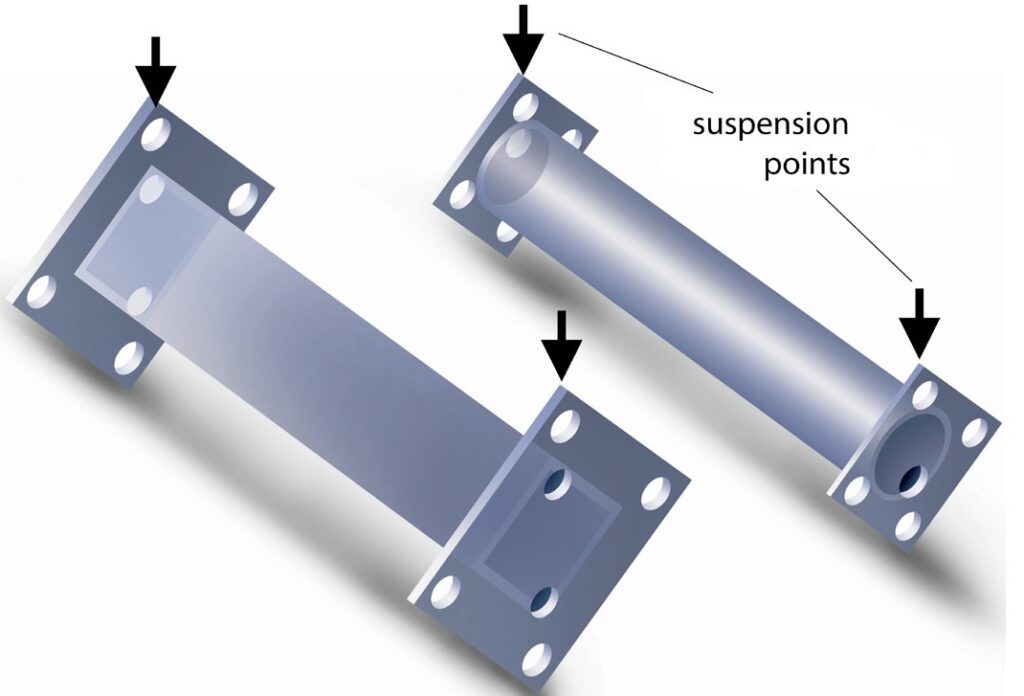

For complete protection, molten zinc must be able to flow freely to all surfaces of a fabrication. With hollow sections or where there are internal compartments, the galvanizing of the internal surfaces eliminates any danger of hidden corrosion during service. LEARN MORE

A proportion of steelwork that is hot dip galvanized is subject to fabrication by welding prior to dipping. The welding process can affect galvanizing in terms of coating quality, distortion and creating an increased potential for cracking in isolated instances. By taking suitable actions these issues may be alleviated. LEARN MORE

There are several different methods that may be used to prevent a coating from forming on the steelwork, the preferred option being dependent upon the nature of the area which requires masking off. LEARN MORE

The galvanized coating applied by immersion in a bath containing molten zinc not only provides a high level of corrosion protection but is also very robust, such that it will normally withstand handling and erection. However, the coating may occasionally be subject to small areas of mechanical damage typically as chips at edges or corners when mishandled. In such instances, it is necessary to repair the galvanized coating. LEARN MORE

Contact our team

Over the past 50 years, Galco has become a recognized leader offering high quality equipment and systems. We are dedicated to exploring the latest construction technologies to generate cost savings for clients.

Send Us a Message

Fields marked with an * are required

"*" indicates required fields